|

|

|

|

|

| |

Definition 1:

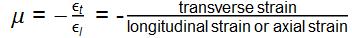

Poisson's ratio is the ratio of transverse contraction strain to longitudinal extension strain in the direction of stretching force. Tensile deformation is considered positive and compressive deformation is considered negative. The definition of Poisson's ratio contains a minus sign so that normal materials have a positive ratio.

Definition 2:

Poisson's ratio is the ratio of the relative contraction strain (or transverse strain) normal to the applied load - to the relative extension strain (or axial strain) in the direction of the applied load.

Typical Poisson's Ratio's for some Common Materials

| Material |

Poisson's Ratio

μ |

| Upper limit |

0.5 |

| Aluminum |

0.334 |

| Aluminum, 6061-T6 |

0.35 |

| Aluminum, 2024-T4 |

0.32 |

| Beryllium |

0.08 |

| Beryllium Copper |

0.285 |

| Brass, 70-30 |

0.331 |

| Brass, cast |

0.357 |

| Bronze |

0.34 |

| Concrete |

0.1 - 0.2 |

| Copper |

0.355 |

| Cork |

0 |

| Glass, Soda |

0.22 |

| Glass, Float |

0.2 - 0.27 |

| Gold |

0.44 |

| Granite |

0.2 - 0.3 |

| Ice |

0.33 |

| Inconel |

0.27 - 0.38 |

| Indium |

0.45 |

| Iron, Cast - gray |

0.211 |

| Iron, Cast |

0.22 - 0.30 |

| Iron, Ductile |

0.26 - 0.31 |

| Iron, Malleable |

0.271 |

| Lead |

0.431 |

| Limestone |

0.2 - 0.3 |

| Magnesium |

0.35 |

| Magnesium Alloy |

0.281 |

| Marble |

0.2 - 0.3 |

| Molybdenum |

0.307 |

| Monel metal |

0.315 |

| Nickel Silver |

0.322 |

| Nickel Steel |

0.291 |

| Polystyrene |

0.34 |

| Polystyrene foam |

0.3 |

| Phosphor Bronze |

0.359 |

| Fused quartz |

0.17 |

| Rubber |

0.48 - ~0.5 |

| Stainless Steel 18-8 |

0.305 |

| Steel, cast |

0.265 |

| Steel, Cold-rolled |

0.287 |

| Steel, high carbon |

0.295 |

| Steel, mild |

0.303 |

| Titanium (99.0 Ti) |

0.32 |

| Tungsten |

0.28 |

| Wrought iron |

0.278 |

| Z-nickel |

0.36 |

| Zinc |

0.331 |

|

|

|

|

|