|

|

|

|

|

| |

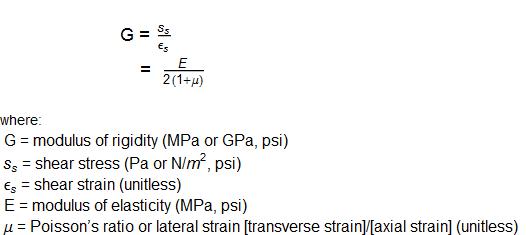

Modulus of Rigidity or Shear Modulus is the coefficient of elasticity for a shearing or torsion force.

It is defined as the ratio of (shear stress) to the displacement per unit sample length (shear strain.)

Modulus of Rigidity can be experimentally determined from the slope of a stress-strain curve created during a tensile tests conducted on a sample of the material.

Modulus of Rigidity of some Common Materials

| Material |

Shear Modulus

- G - |

| (106 psi) |

(GPa) |

| Aluminum Alloys |

3.9 |

27 |

| Aluminum, 6061-T6 |

3.8 |

24 |

| Aluminum, 2024-T4 |

4.0 |

28 |

| Beryllium Copper |

6.9 |

48 |

| Brass |

5.8 |

40 |

| Bronze |

6.5 |

44.8 |

| Cadmium |

|

19 |

| Carbon Steel |

11.2 |

77 |

| Cast Iron |

5.9 |

41 |

| Chromium |

|

115 |

| Concrete |

3.0 |

21 |

| Copper |

6.5 |

45 |

| Glass |

|

26.2 |

| Glass, 96% silica |

2.8 |

19 |

| Inconel |

11.5 |

79 |

| Iron, Ductile |

9.1 - 9.6 |

63 - 66 |

| Iron, Malleable |

9.3 |

64 |

| Kevlar |

2.8 |

19 |

| Lead |

1.9 |

13.1 |

| Magnesium |

2.4 |

16.5 |

| Molybdenum |

17.1 |

118 |

| Monel metal |

9.6 |

66 |

| Nickel Silver |

6.9 |

48 |

| Nickel Steel |

11.0 |

76 |

| Nylon |

0.59 |

4.1 |

| Phosphor Bronze |

5.9 |

41 |

| Plywood |

0.09 |

0.62 |

| Polycarbonate |

0.33 |

2.3 |

| Polyethylene |

|

0.12 |

| Rubber |

|

0.0003 |

| Structural Steel |

11.5 |

79.3 |

| Stainless Steel |

11.2 |

77.2 |

| Steel, Cast |

11.3 |

78 |

| Steel, Cold-rolled |

10.9 |

75 |

| Tin |

|

18 |

| Titanium, Grade 2 |

5.9 |

41 |

| Titanium, Grade 5 |

5.9 |

41 |

| Titanium, 10% Vanadium |

6.1 |

42 |

| Tungsten |

|

161 |

| Wood, Douglas Fir |

1.9 |

13 |

| Zinc |

|

43 |

| Z-nickel |

11 |

76 |

- 1 GPa = 0.145x106 psi (lbf/in2)

- 1 x 106 psi = 6.9 GPa

|

|

|

|

|